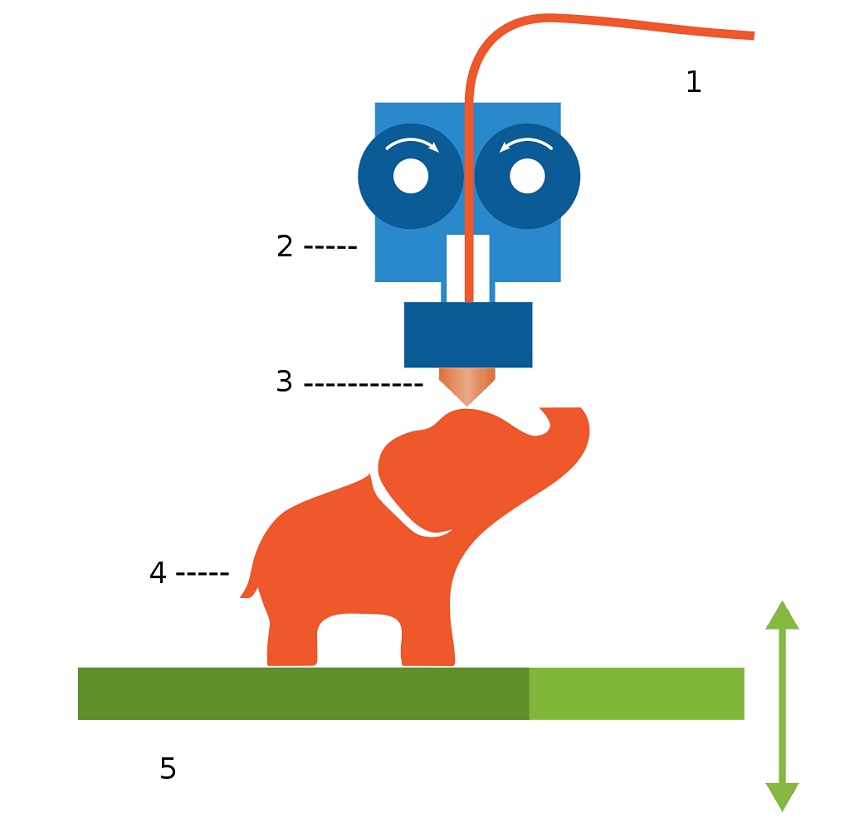

Fused Deposition Modelling (FDM) 3D printers use an extruder that is responsible for pushing the filament into a heater and nozzle assembly ultimately resulting in the deposition of the filament onto the build platform. This can either be a Bowden extruder or a Direct Drive Extruder.

While the ultimate purpose of both these systems is same, the assembly is slightly different. In a direct drive system, the extruder is mounted on the printhead which pushes the material directly into the nozzle. In a Bowden system, the extruder is mounted on to the printer frame and thus is at some distance from the nozzle. Thus the printhead receives the filament via a PTFE tube.

As explained, both systems perform the same function albeit with a slight variation and this variation induces some advantages and some disadvantages into the printing process impacting the performance of the 3D printer.

Bowden extruder

Unlike the direct drive extruder, the Bowden extruder (A) is attached to the frame of the 3D printer and pushes the filament (B) through a long PTFE tube (Bowden tube) into the hotend (C).

PROS

Less weight on the printhead / less moving mass

Since the printhead can work without additional weight, the following advantages result:

· Clean movements

· Increased printing speed

· Nice prints due to reduced vibration on the printhead

CONS

· More powerful motor needed

A Bowden extruder requires a more powerful motor with more torque to control the filament because it has to be pulled through the PTFE tube.

· Slower response time

Increased friction in the Bowden hose leads to a reduced reaction time. Bowden extruders require longer and faster retraction to avoid tension.

· Smaller range of compatible filaments

Flexible or abrasive filaments can wear out more in the Bowden hose and are processed more poorly than with the direct drive extruder due to the longer conveying path.

Direct extruder

The direct drive extruder (A) is installed with the hotend (C) and pushes the filament (B) directly into the nozzle (D). All filament processing components are therefore located in one place on the print head. This creates advantages and disadvantages that you should consider before buying a printer.

PROS

· Better extrusion

Since the extruder is located directly on the print head, the motor can simply push the filament through the nozzle.

· Faster retraction

Due to the proximity of the extruder and nozzle, the filament can be retracted quickly; in many cases, no retraction setting is necessary.

· Weaker, smaller motors are possible

Because of the short distance between extruder and nozzle, less torque is required from the motor to push the filament.

· Wider range of compatible filaments

Direct extruders are compatible with a wide range of filaments - they print reliably even with abrasive and flexible materials.

CONS

· More weight on the printhead

Since the extruder is mounted on the hotend, it has more weight. The increased weight has the following disadvantages:

· More power requirement

· Increased wear on toothed belts and bearings

· Printing speed is reduced

· More complex maintenance

After the feed and the hotend are built directly together, maintenance such as cleaning the nozzle proves to be more difficult.

So, which systems is better you ask? Well, any system you use, be it a Bowden Extruder or a Direct Drive Extruder, both have its own advantages and disadvantages. The choice completely depends on a few factors that you should consider before making a decision.

Final Thoughts

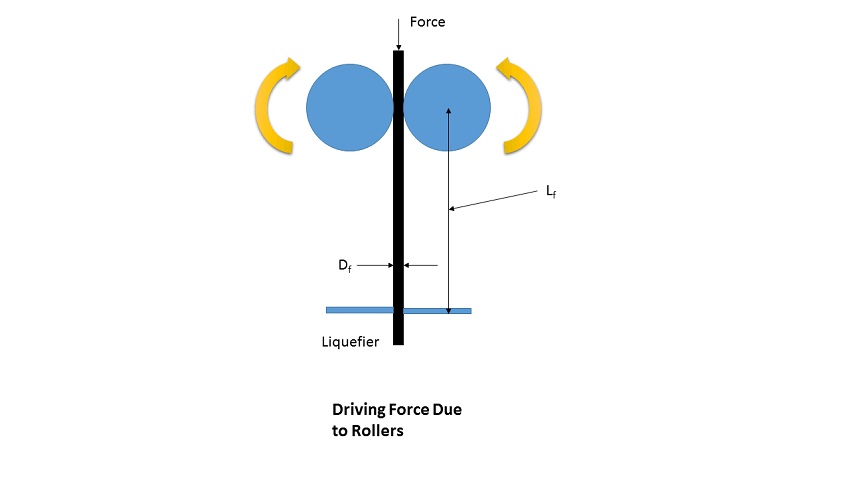

Both direct drive and bowden extrusion systems use a stepper motor and drive gears to feed filament (push and retract) into the 3D printhead.

1. The key difference between the two extrusion systems is that direct drive extruders are mounted onto the printhead, while bowden systems are mounted onto the printer’s frame.

2. Direct drive extruders offer better extrusion and retraction control and the stepper motor requires less power to feed the filament into the printhead.

3. Direct extrusion works well with most filaments, including flexible filaments and fiber-filled materials.

4. Bowden extruders use a tube to feed the filament from the extruder to the printhead. They enable faster, smoother printing (less wobble) because there is no added weight on the printhead.

Conclusion - which extruder should you choose?

Both extruder variants have their advantages and disadvantages. The biggest difference is clearly to be found in the processing of flexible filaments. If you want to print quickly and do not use flexible filament, you can use a Bowden extruder.

However, if you want to process flexible materials, a direct extruder is definitely recommended.

(1)-ZI1.webp)